Development of a Revolutionary Approach for Efficient Microgravity Transfer Line Chilldown

PI: Jacob Chung, University of Florida - Gainesville

PI: Jacob Chung, University of Florida - Gainesville

- TA01 Launch Propulsion Systems

- TA02 In-Space Propulsion Technologies

- TA14 Thermal Management Systems

When transferring propellant from a supply tank to a receiver tank, the transfer pipe and receiver tank are at a very high temperature compared to the propellant. Chilldown is the process of introducing the cryogenic propellant into the system, forcing the hardware to cool down to the liquid temperature. The propellant boils off as it cools the line and tank until they reach the liquid temperature. Since the propellant is only storable and useful to the engine in pure liquid form, this vaporized propellant is vented overboard and considered lost. Efficiency for pipe chilldown is very low in 0g, much lower than chilldown in normal gravity due to the different flow patterns that occur. Only 8% of the cooling capability of cryogen is used and 25% of the propellant is spent during propellant transfer. This effort is focused on 0g chilldown of the transfer pipe, although this project is also considered a stepping stone to eventually performing 0g chilldown of a receiver tank.

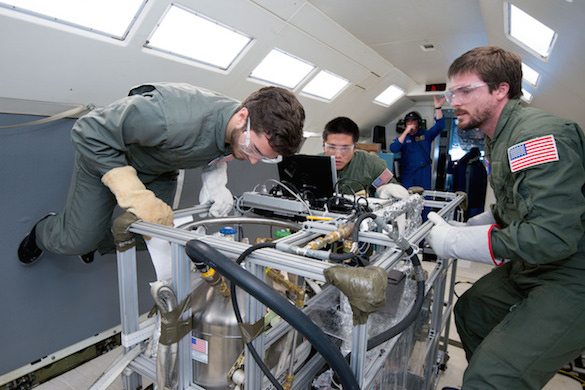

The experiment will be carried out on a parabolic aircraft. Liquid nitrogen will be transferred through several pipe test sections equipped with thermocouples and pressure sensors to measure chilldown heat transfer and fluid properties.

Technology Details

-

Selection DateREDDI-F1-16 (Jul 2016)

-

Program StatusActive

- 2 Parabolic

Development Team

-

PIJacob Chung

-

Organization

-

SponsorUniversity of Florida

-

PartnersNASA/Glenn Research Center, NASA/Kennedy Space Center, United Launch Alliance